36

of the mean volume (hydrostatic) stress

σ

m

relative to the resulting von Mises effective

stress,

σ

e

, i.e.

h =

σ

m

/

σ

e

. According to plastic theory laws, especially in case of metals, the

mean „hydrostatic“ stress of the system will never cause yield, no matter how large the

stress. Therefore, the size of plastic increments depends only on components of the so-

called deviatoric stress, and in the case

h =

1 plastic deformation will not occur.

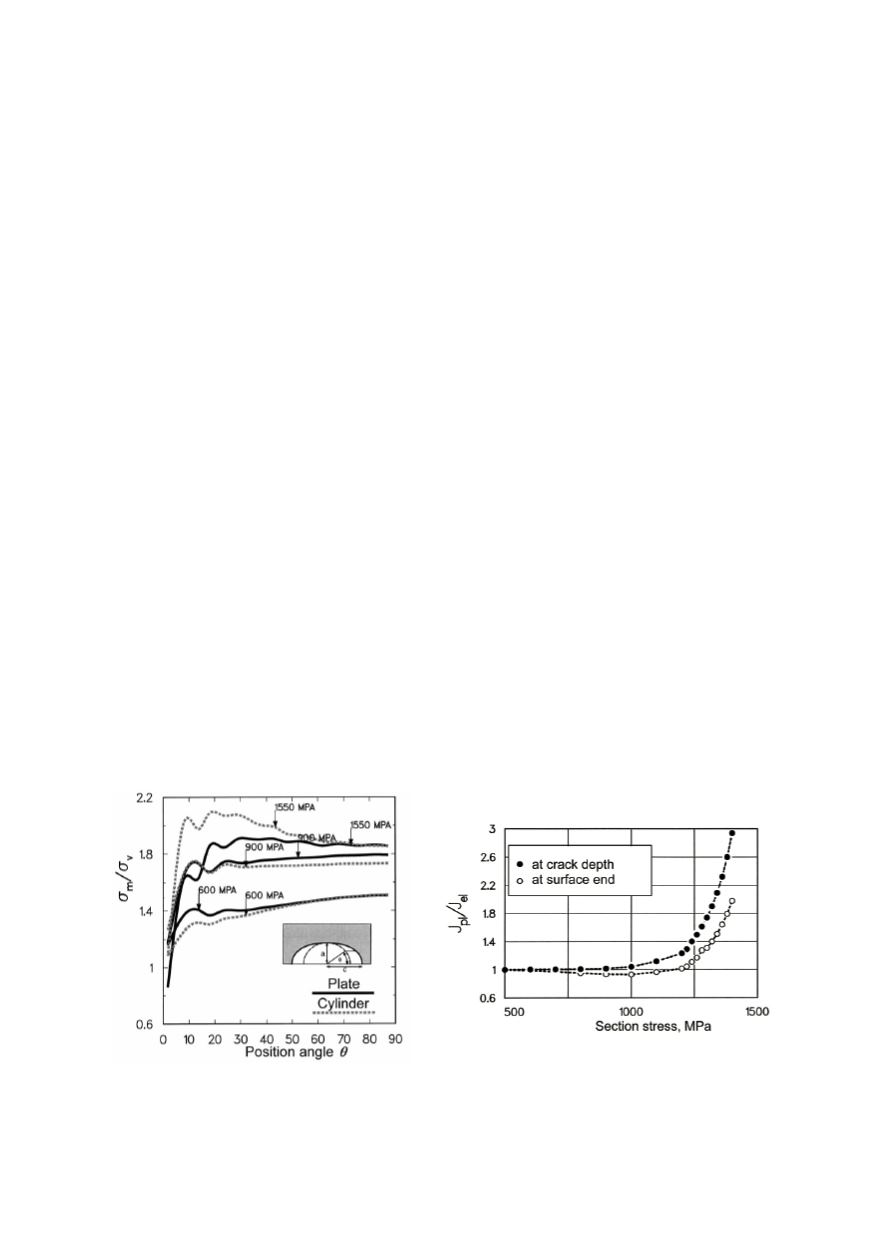

Complexity of the conditions for volume cracks shows the results of FEM-calculation

for surface crack in Fig. 18. Near the surface the yielding is free and

h

takes minimal

values. However, the value of the constraint parameter

h

increase inside the crack, what is

not difficult to imagine, and in case of cylinder under pressure the maximal values is even

between surface and depth (ligament) of the crack. The consequences of this are shown in

Fig. 19. In spite of load increase the values of

J

- integral at the surface are on account of

plasticity in decrease and only after crossing into full plasticity increase arise that,

however, fall back compared to the crack depth position. Obviously, the application of

elastic solution (

K

) is not sufficient to evaluate relationship along crack contour.

High degree of constraint leads to the faster fracture. Because the energy introduced in

system (the value is measured by

J

- integral) is dissipated based on plastic deformation

in smaller extent, and therefore stay available for fracture initiation. It is obvious that the

constraint is significant parameter for fracture mechanics to establish the safe fracture

criteria. But, important problem exist, because of the constraint conditions for specimens,

which are small, compared to the real structure, so that the data transfer could be unsafe.

The constraint effect is observed from early beginning of the fracture mechanics

development. Limitation to the 2-dimesional through crack showed the consequences

already by the selection of specimens. However, former only two extreme cases, plane

stress and plane strain has been shown to be insufficient.

Figure 20 shows that, due to different conditions on the external surfaces and inside of

the specimen the size of the plastic zones is different, and material resistance at specimen

surfaces is higher than inside it. In Fig. 21 various forms of fracture surfaces for 2-

dimensional specimens are shown. An initially straight front bends at ends with the

growth before the instable fracture onset. Interior to the plate, there prevails a high

constraint effect leading to crack growth profile similar to the beginning. At specimen

edges there is no constraint and the energy is more dissipated in distortion.

Figure 18. Degree of constraint along crack

profile (comparison of plate and cylinder)

Figure 19.

J

- integral development for situations

in Fig. 18