100

specimen is valid for

a

/

W

> 0.2, and for M(T) (Fig. 15) for 2

a

/

W

< 0.95. The use of

stress-intensity expressions outside prescribed region can produce errors in results.

Center-cracked tension specimens

Δ

K

value

2

2

P a

K

sec

B W

π

πα

Δ

Δ =

α

= 2

a

/

W

Expression valid for 2

a

/

W

< 0.95

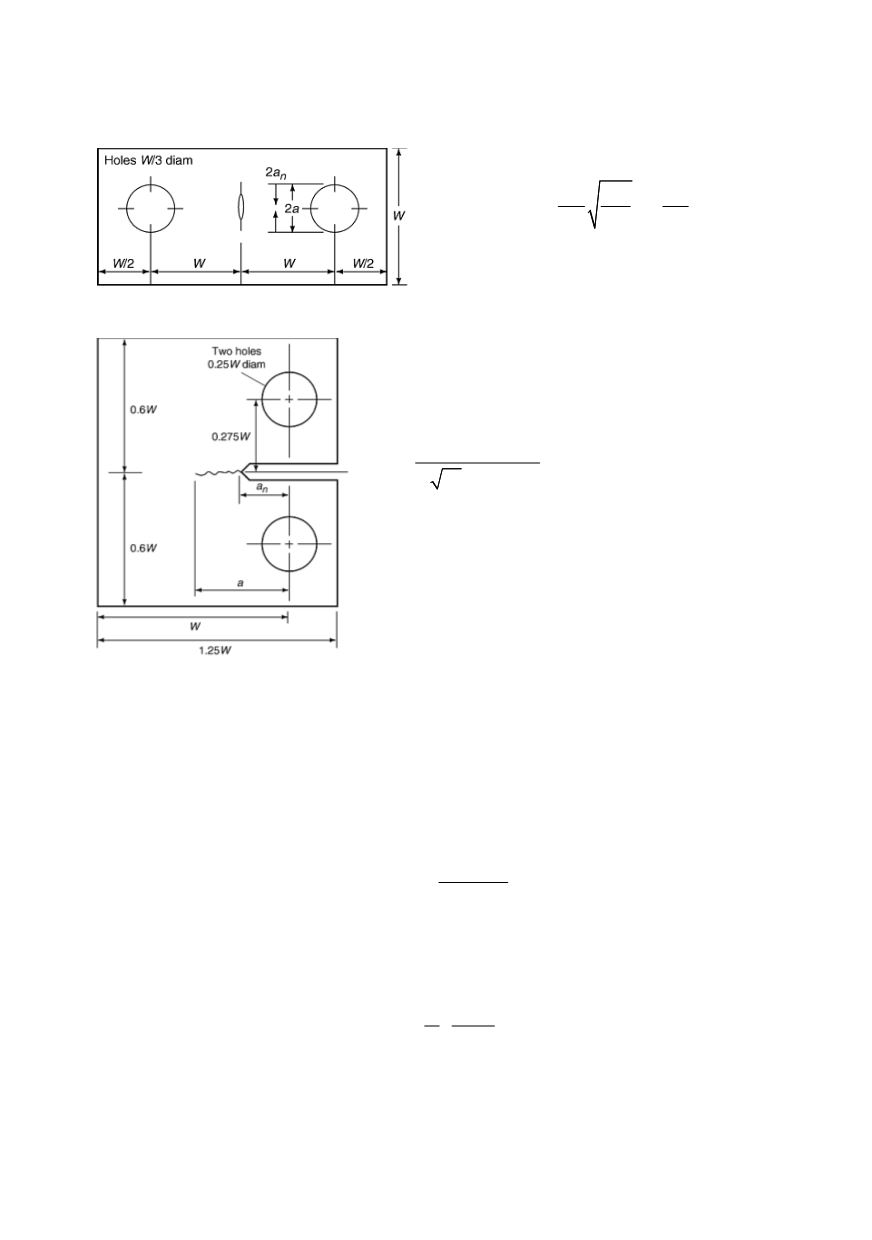

Figure 14: Standard center cracked tension - Middle-tension M(T), and

ΔK

solution

Compact-type specimens

Δ

K

value

(

)

(

)

2

3 2

3

4

2

0866 4 64 13 32

14 72 5 6

1

/

P a

.

.

K

.

.

B W

α

α

α

α

α

⎛

⎞

Δ +

+

− −

+

⎜

⎟

Δ =

⎜

⎟

+

−

− ⎝

⎠

α

=

a

/

W

Expression valid for a/W < 0.2

Figure 15: Standard compact-type specimen - C(T), and

ΔK

value /25/

The size of the specimen must also be appropriate. To follow the LEFM rules the

specimen must be tested in elastic range. However, unlike the requirements for plane-

strain fracture toughness testing, the stresses at the crack tip do not have to be in a plane-

strain state, but stress state should be controlled by test variable, according to material

properties, specimen size, crack length, and applied load. Since the loading modes of

different specimens vary, each specimen geometry must be considered separately.

For the center-cracked tension M(T) specimen, it is required that:

1 25

2

max

YS

. P

W a

B

σ

− ≥

(6)

where

W

- 2

a

is the uncracked ligament of the specimen (Fig. 14) and

σ

YS

is the 0.2%

offset yield strength at the temperature corresponding to the FCGR data.

For the compact-type C(T) specimen, it is required that:

2

4

max

YS

K

W a

π σ

⎛

⎞

− ≥ ⎜

⎟

⎝

⎠

(7)

where

W

-

a

is the uncracked ligament (Fig. 7). For C(T) specimen, the size requirement

in Eq. (7) limits the monotonic plastic zone in a plane-stress state to about 25% of the un-

cracked ligament. For both Eqs. (6) and (7), the size requirements are appropriate for