104

measure the maximum applied load and resolve the lowest expected amplitudes, as

specified in ASTM E 4.

When testing in environments, specimens fit inside furnaces or cabinets with ample

space left for clevises, cantilever beam clip gauges, and other hardware.

Gripping of the specimen

must be done in a manner that does not violate the stress-

intensity solution requirements. In grips that are permitted to rotate, such as the compact-

type specimen grip, the pin and hole clearances must be designed to minimize friction.

The alignment of the system should be checked carefully to avoid undesirable bending

stresses and uneven cracking. Alignment can be easily checked using a strain gauge

specimen. Gripping arrangements for compact-type and center-cracked tension specimens

are described in ASTM E 647 /25/.

4.2.5. Loading

The loading conditions play an important role, and load ratio,

R

, residual stresses,

K

-

gradients, and small-scale yielding (SSY) should be considered. All specimen geometries

are well suited for tension-tension (

R

> 0) testing. However, tests that call for negative

R

are restricted to symmetric, wedge-grip loaded specimens, like the middle-tension speci-

mens, sensitive to compressive loads and moving through zero loads.

Residual stresses in the material have a marked effect on FCGR and if they are

through the thickness, perpendicular to the direction of crack growth, may accelerate or

retard crack growth. When these stresses are not uniform, the ASTM E 647 recommends

a reduction of the thickness-to-width ratio (

B

/

W

).

The rate at which

K

increases as the crack extends at a constant-load amplitude is

given by the geometry function

f

(

a

/

W

) and may be considered when selecting the most

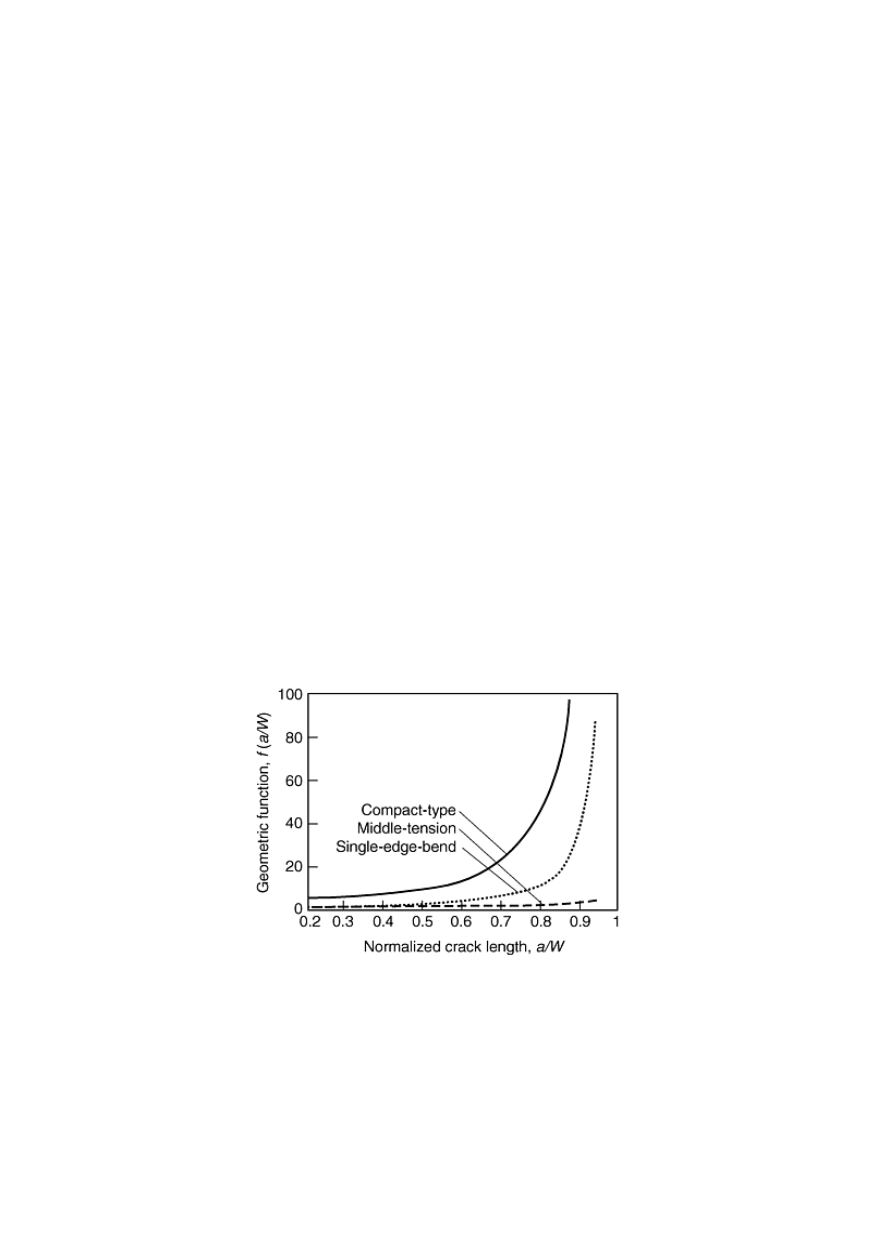

appropriate specimen geometry. Figure 17 shows the effect of geometry on the

K

-

gradient through a variety of specimen geometries. Specimens with shallower

K

-gradients

are preferable for brittle materials, while the opposite is true for ductile materials.

Figure 17: K-gradients for a number of fatigue crack growth specimens

4.2.6. Crack length measurement

Precise measurements of fatigue crack extension are crucial for the determination of

reliable crack growth rates. ASTM E 647 requires a minimum resolution of 0.1 mm in

crack length measurement. Various crack measurement techniques have been applied,

including optical (video, visual and photographic), ultrasonic, acoustic emission,

electrical, and compliance (displacement and back face strain gages) methods.