109

It is possible to use this procedure for any single component of a structure, and in this

manner to reduce the number of critical components in a structure. Specifying real critical

components it is also possible to reduce the number of necessary inspections, since for

less critical components the frequency of inspection might be reduced. In this way, the

expenses for non-destructive inspection (NDI) testing could be reduced without inc-

reasing risk for fracture, enabling in the same time servicing lifetime extension.

It is to notice that applicable testing for structural integrity are non-destructive (like

ultrasonic, radiography, magnetic particles, visual) for detecting defect shape, size and

position, and destructive for determination of material properties, and material resistance

to crack initiation and propagation. The resistance to the crack propagation should be

measured under the same condition (environment and loading) to which a structure is

exposed in service. A unified approach does not exist on how to achieve safe usage of a

structure. The main problem is the number of different structures with many different

components and critical parts, most dangerous of can cause failure of the structure.

3. DESIGN STAGE

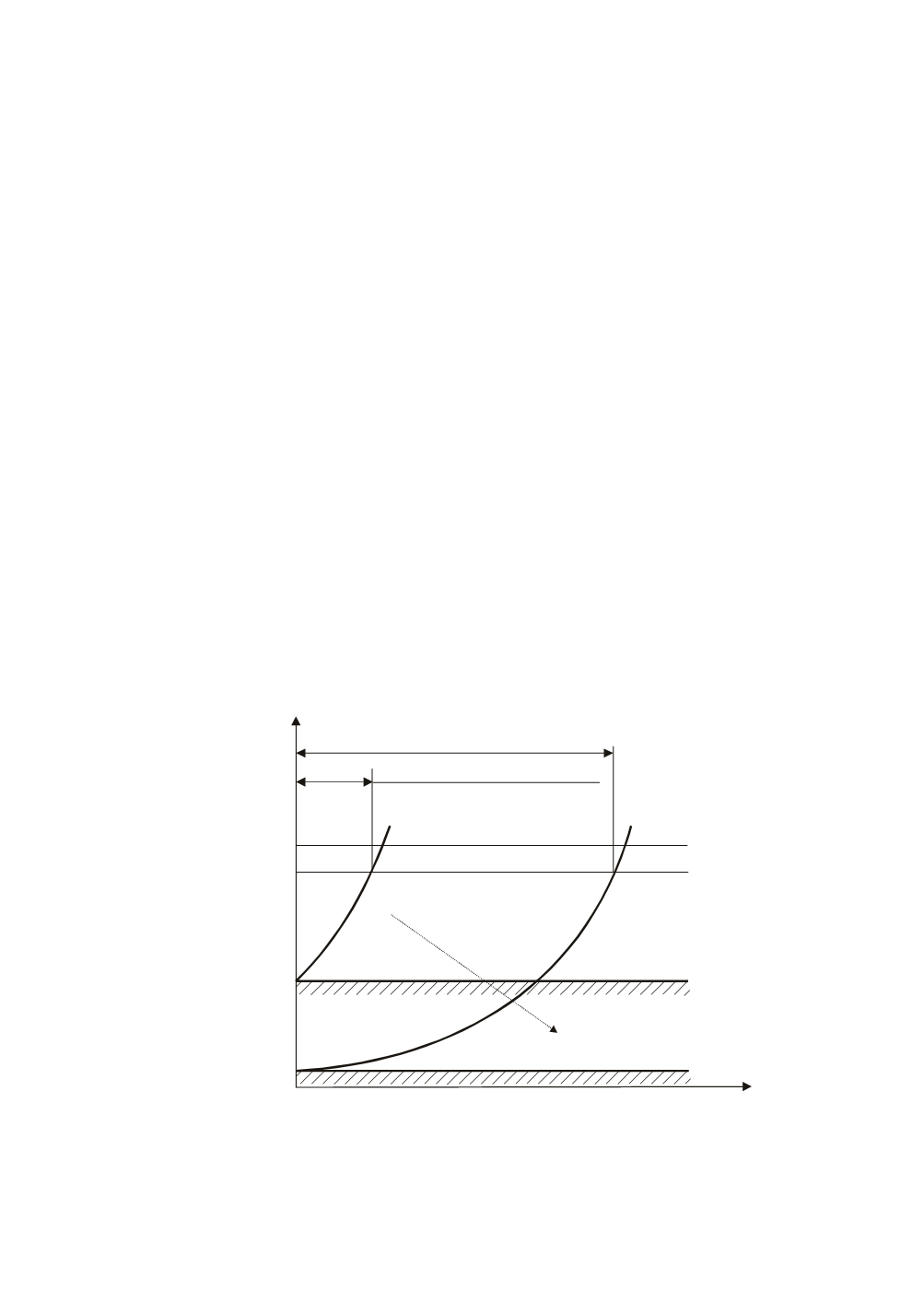

In the design stage, two basic activities run together. The first activity is connected

with crack detection and its significance assessment. It is important here to recognize the

exact capabilities and sensitivity of the non-destructive testing (NDT) equipment, which

determine minimum detectable crack size, important for consideration in design. It is

clear that postulated crack size in design is limited by the sensitivity of NDT equipment.

The servicing lifetime lasts corresponds to the time from crack growth, from postulated to

critical crack size. Here are most interesting cracks which can grow in fatigue or in creep,

and for that specimens for crack propagation have to be subjected to the same loading

conditions and environment as the structure. The effects of sensitivity and the quality of

the NDT equipment on designed lifetime are shown in Fig. 2.

design life time - DLF b)

design life time - DLF a)

better NDI equipment

crack growth

crack growth

Crack size parameter

a

crit

a

crit

80%

a NDI

=

a)

b)

0

a a

= NDI

min

time

0

Figure 2: Effect of NDI equipment quality on design lifetime of structure

The second activity set consists of material testing, stress analysis and determination

of critical structural sections of structures, necessary from the very beginning of design.