63

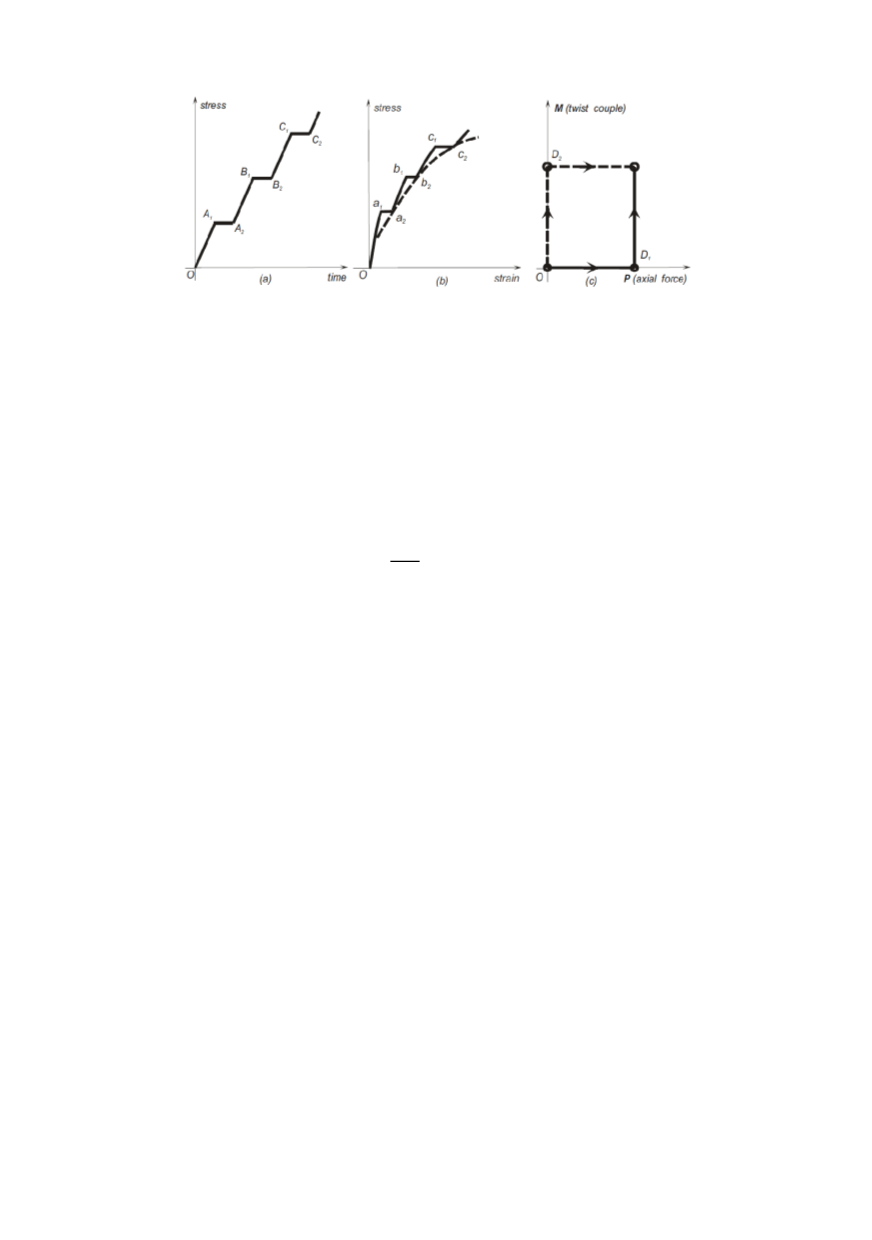

Figure 5: Subfigures (a) and (b) show staircase stress paths aimed to detect static yield surface

/15/, while at subfigure (c) Hohenemser classical non-proportional stress paths are shown

Schwer et al reported experiments on cylindrical tanks under and without internal

pressure when hit, locally to a spot, radially by a stream mild detonating fuze /13/. They

concluded that deformability is considerably reduced by internal pressure. The relation-

ship of this experiment to an experiment by means of biaxial Hopkinson bar in Dynamic

material testing laboratory in JRC-Ispra was discussed in /5/.

Mason et al measured continuously during Hopkinson bar experiment change of

temperature in order to calibrate Г in the equation for transfer of plastic work into heat

/12/

݀Θ ൎ െ Г

ߩ

ܿ

݀መ ܹ

(85)

under assumption of adiabatic conditions and small elastic strain as in Ref. /33/. The

measurement was performed by high speed infrared detectors. Although such an

experiment is not devoted to failure, measurement of detecting temperature is important,

/25/.

Multiaxial tests aimed to characterize inelastic behaviour of steel and other materials

by means of sophisticated specimen (like “bicchierino” and cruciform specimen, Ref.

/32/) have been made in Dynamic material testing laboratory of the Institute of nuclear

safety (JRC) in Ispra during last years. The accumulated experience allows a new more

profound insight into most interesting material behaviour at complex stress paths leading

to multiaxial stress as well as strain states. From this experience and other experimental

as well as theoretical work two principal features should be on-line detected during each

test namely

–

time dependent change of temperature; and

–

plastic volume change, especially at advanced stage of failure process.

The obtained results are presented in /32/ and the other reports by Mićunović for this

for this laboratory covering multiaxial stress-strain histories, as well as in small to high

strain rate ranges.

4. CONCLUDING REMARKS

Some results to be noted are the following:

–

Clear procedure of treatment of test records obtained by strain gauge as well as photo

recorded grid measurements is given. This procedure given in the appendix shows how

to get correct stress and strain measures at finite strains, static as well as dynamic tests

in order to perform constitutive modelling and localization analysis. The corresponding

program is written in MATLAB-code in such a way that once Lagrangian total strain