58

ݑ

ൌ ൜ 1 2ܴ 1 ܴ ൠ

ଵ ଶ⁄

ሼሺ1 ܴሻሺ1 ݉

ଶ

݂

ଶ

ሻ െ 2ܴ݂݉

ሽ

ଵ ଶ⁄

(66)

where

݂

ݐ ؠ

ଵ

ݐ

ଵ

⁄

. The criterion of instability onset is postulated by the equality

݀

ߝ

ҧ

݀

ߝ

ҧ

|ఌതୀఌത

ಾ಼

כ

ൌ 0

giving the limit strain

ߝ

ҧ

ெ

כ

ൌ

ߝ

ҧ

௨

. For a very ductile steel sheet with

m

= 1;

R

= 1;

n

= 0.2

and

ߝ

ൌ 0.00136

the authors have found that

0.98 ൏ ݂

൏ 0.99

fits experimental limit

strain

ߝ

ഥ

כ

ൎ 0.82,

(cf. Figure 1.5 in M-K, 1967). When

݂

՜ 1

, then

ߝ

ҧ

ெ

כ

՜ ∞

. The

above, here given, formulae are slightly different than the corresponding in Ref./22/

correcting their typographical mistakes and applying the invariant formulation given

Ref./22/

.

In the paper /22/ the authors analysed in detail also the other factors influencing

ߝ

ҧ

ெ

כ

such as

m, n,

ߝ

and

R

. They gave the important note that a linear initial distribution of

voids could have similar effect as initial geometric imperfection

݂

.

2. In paper /21/ Korhonen considered localized instability in the same way as in pre-

vious text for isotropic and transversely isotropic metal sheets using Eq. (64) in Ref./22/,

corrected for their typographical mistakes. He did not try, however, to derive these

equations for the case of orthotropy which is usually induced by rolling of car body

sheets.

On the other hand he wanted to compare diffuse instability criterion with the localized

instability criterion.

After solving some typical stress states and some characteristic material symmetry,

Korhonen drew following conclusions:

–

a minimum in M-K limit curves in (

ߝ

ଵ

ߝ ,

ଶ

) diagrams - forming limit diagrams (FLD)

may appear near plane strain states where

ߝ

ଶ

ൎ 0,

ߝ

ଷ

ൎ െ

ߝ

ଵ

caused by

ߪ

ଵ

ൎ 2

ߪ

ଶ

in

the considered cases of isotropy and transverse isotropy;

–

M-K limit curves are higher when

R

in Eq. (62) is smaller, i.e. when ratio of in-plane

yield stress versus normal-to-plane yield stress (

ߪ

௬ଵ

ߪ/

௬ଷ

) decreases;

–

sensitivity of M-K limit curves to material anisotropy is higher than sensitivity of Hill's

(i.e. diffuse) limit curves;

–

according to M-K limit curves maximal limit strains there appear during equibiaxial

tension, whereas in Hill's limit curves a maximum between equibiaxial tension and

plane strain usually appears

–

Hill's necking subtangent is heavily influenced by the shape of function i.e.

ߪ

ത ൌ

ߪ

ത൫

ߝ

ҧ

൯

.

Its dependence on strain rate as well as temperature are often indispensable.

3. The best way to see applicability of a criterion is to apply it at diverse stress states

and a real material. For this sake let us consider an by aluminium killed steel sheet, made

of C0148P5 (JUS standard) equivalent to DIN St 24 of following chemical composition

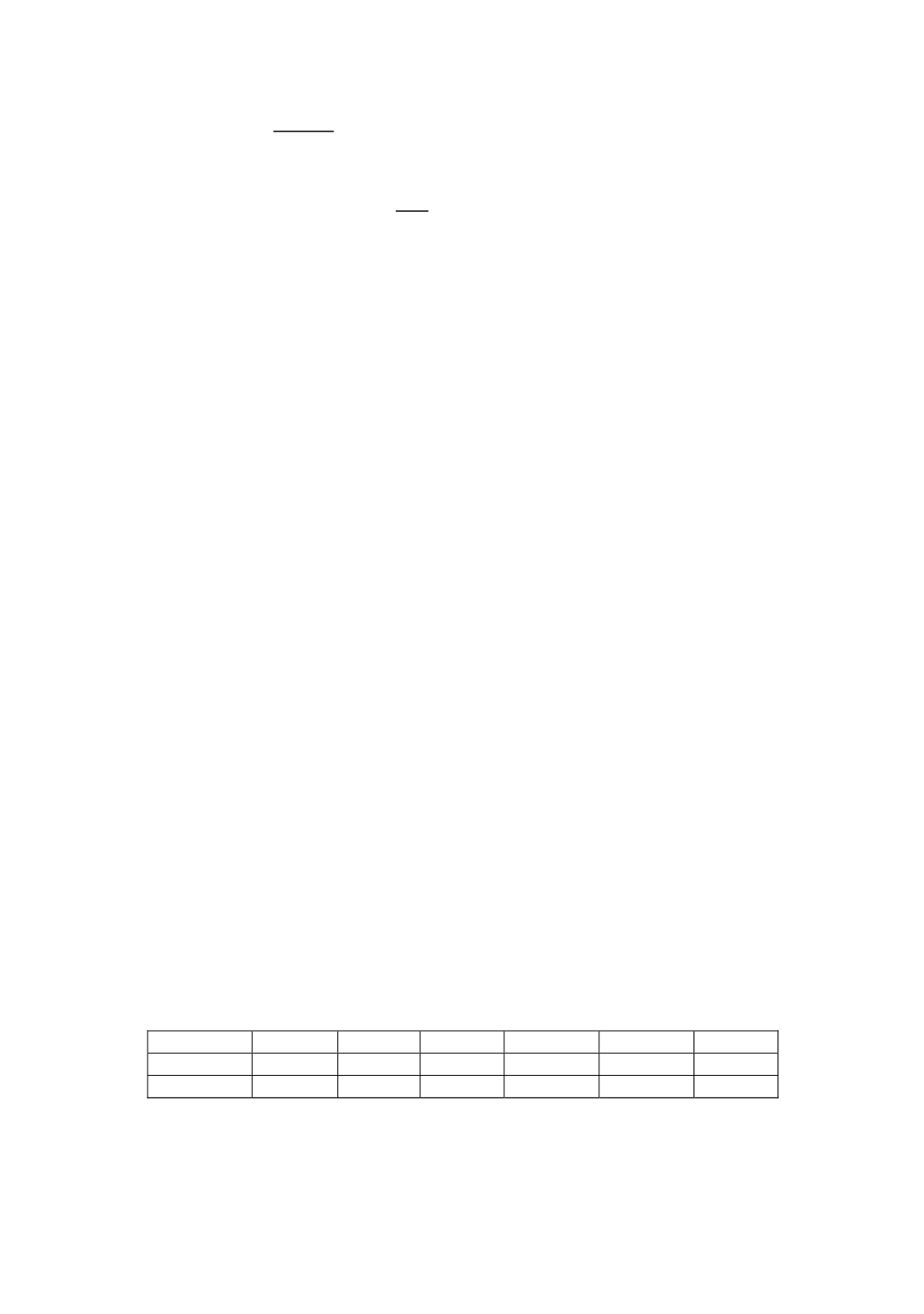

C

Mn

Si

P

S

Al

standard

0.08

0.45

traces

<0.03

<0.03

<0.02

measured

0.05

0.21

traces

0.012

0.019

0.07

and large randomly oriented ferritic grains oriented in rolling direction. Stress-strain

relations at strain rate of about 8x10

-3

s

-1

obtained from tension tests read

ߪ

ൌ ܿ

ଵ

ሺ

ߝ

ଵ

ߝ

ଵ

ሻ

ؠ

388.3ሺ0.456

ߝ

.ସସ଼

ሻ

(rolling direction)

ߪ

ൌ ܿ

ଶ

ሺ

ߝ

ଶ

ߝ

ଶ

ሻ

ؠ

405.2ሺ0.444

ߝ

.ସଶ଼

ሻ

(transverse to rolling)

(67)