257

camera and then compares (substracts) both images. The resulting image corresponds to

the vibrations of the surface. The diagrams in Fig. 20 left correspond to two states of a

surface, in non deformed state (up), and in the deformed surface (down) /22/. Phase shift

Δ

between the reference and the object wave is caused by the deformation /23/.

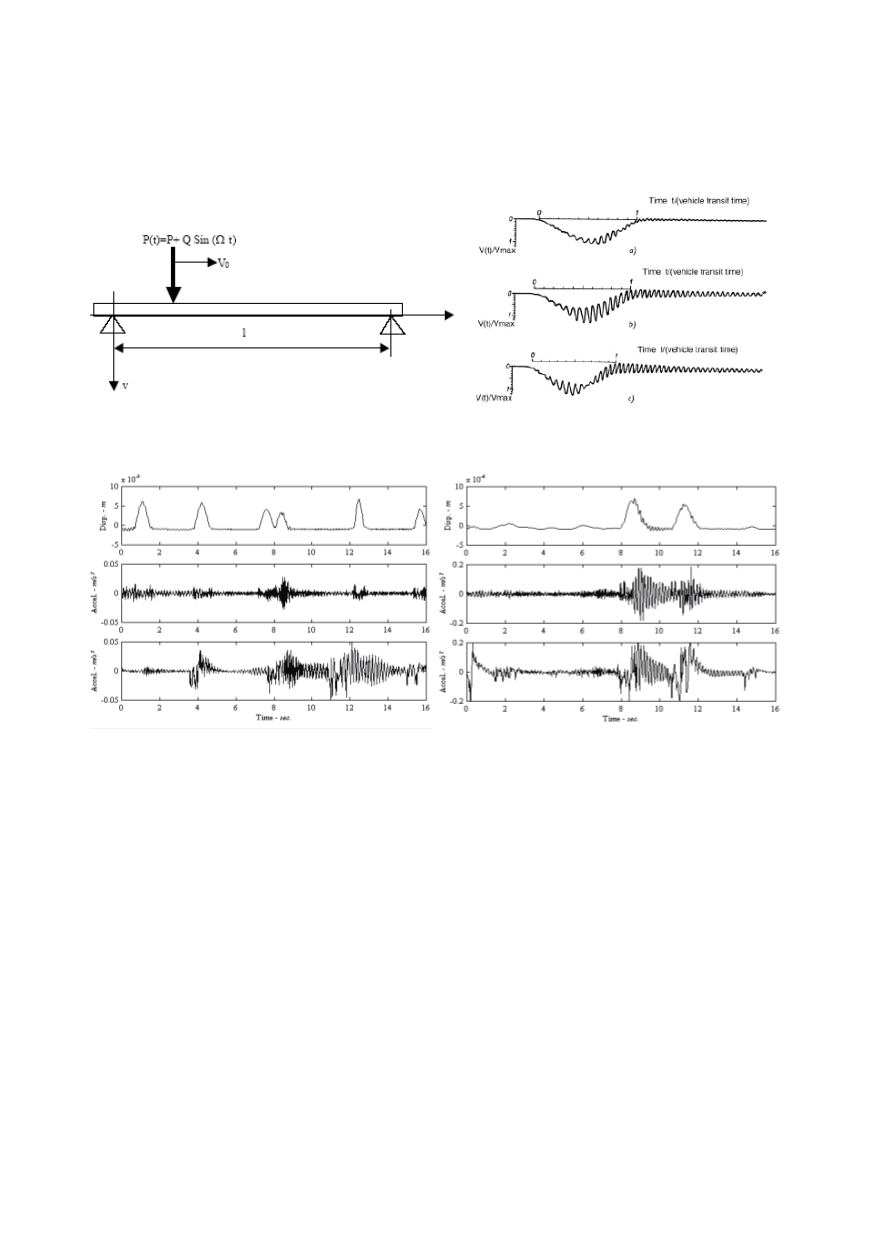

Figure 17: Theoretical model of the beam forced

vibrations

Figure 18: Theoretical solution for beam

midpoint displacement

Figure 19: Comparisons of two direct measurements of displacement by LDV (up), the second

derivatives (middle) and accelerometer signals (down)

Speckle techniques include holographic interferometry, (ESPI, also named television,

electronic, video or digital holography) and shearography. These interferometric techni-

ques require two steps: recording of the object surface, and a second one after applied

stress to the object (e.g. by pressure or thermal stress). After applied stress, displacement

and strain can reveal discontinuities or flaws (as delamination, disbonding or crack).

Laser testing solution for 3D contactless stress and vibration analyses is Vibro-ESPI-

System Q-500 system. It enables highly sensitive full field measurement of harmonic

vibration of component surface. It assures both, static and dynamic, deformation measu-

rements. Ruby laser and three cameras enable various applications (brake squeal, car

body vibration, engine vibrations, shock waves, explosions). Fiber flexible glasses are

used and 1 m

2

area can be analysed. Light modulator and trigger system produce strobos-

copic laser illumination, synchronized to the vibration frequency of the test object /24/. It

is best suited for the development and testing of complex components and structures in

acoustics and stress/strain analysis of electronics, vehicle design, and aerospace. It can be

used for the experimental verification of analytical and numerical calculation techniques.