258

A review of laser vibrometer types and their applications is given in Table 3.

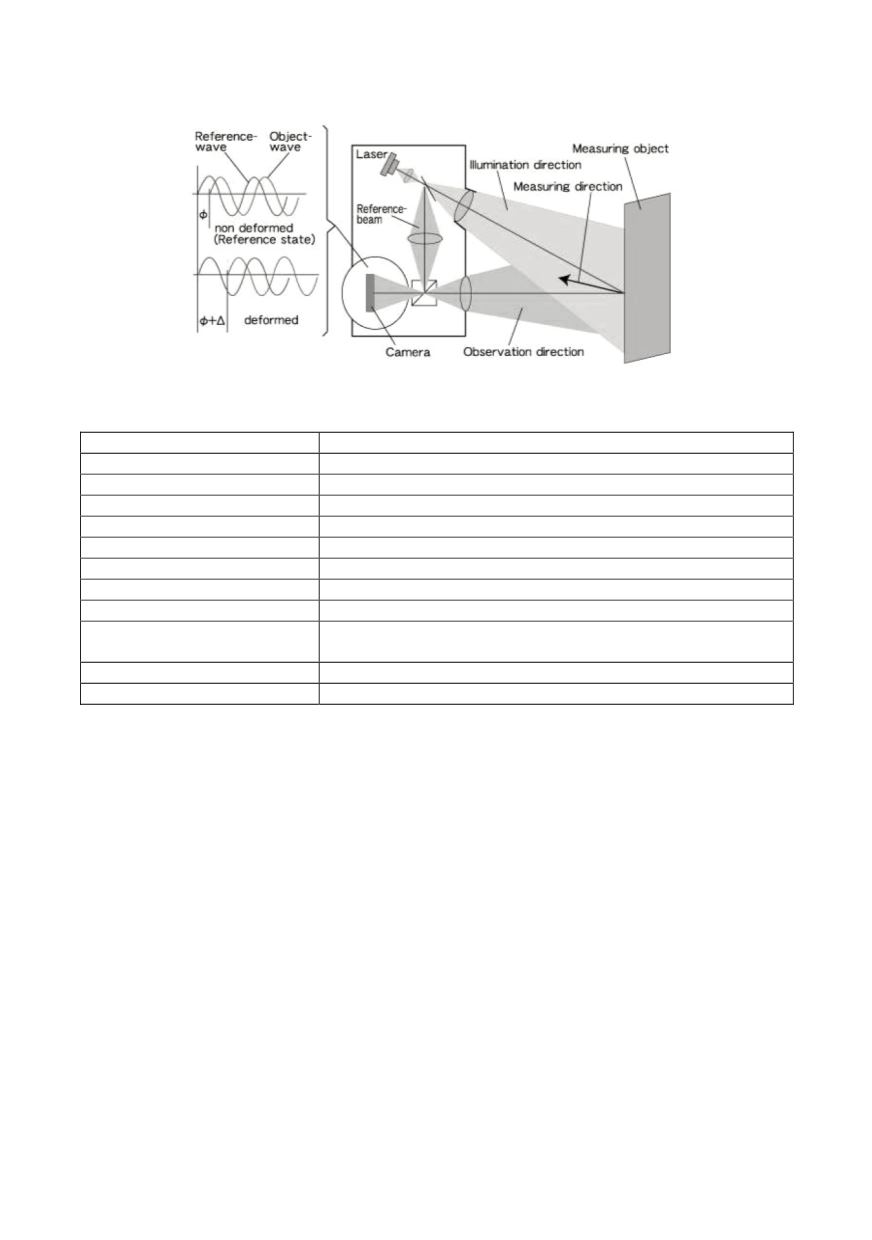

Figure 20: The principle of an electronic speckle pattern interferometry (ESPI system /22/

Table 3: Laser vibrometers and their applications

Vibrometer type

The application

Standard Optic Vibrometers:

Standard optics high sensitivity single point vibrometers

Fiberoptic Vibrometers

Single point, differential and dual channel fiberoptic vibrometers

Scanning Vibrometers

For full field vibration measurements

Rotational Vibrometers

For angular vibration measurements on rotating structures

In-Plane Vibrometers

For 1-D in-plane vibration measurements

Production Vibrometers

Ruggidized industrial type compact vibrometer sensors

3D Vibrometer

For single point simultaneous X,Y and Z measurements

Compact Vibrometers

Compact high sensitivity vibrometers

Digital Vibrometers

Optimized digital decoding techniques for theoretical limit

performance and traceable calibrations

Portable Digital Vibrometers

Portable& affordable

High Speed Vibrometers

For measurements at high vibrational velocities

The examples of ESPI laser interferometry typical results are given in Fig. 21.

Vibration demonstration is typically for loud speaker, different figures can be obser-

ved according to the eigen modes, frequency and amplitude (a). The results obtained with

an excitation frequency ≈ 10 kHz. High frequency mode is prevalent for small separation

between the two shots (40 µs). The second picture is obtained for few seconds separation

of a pulse. A sandwich sample (aluminium skin, honeycomb core) has been tested for

skin-core debonding (b). Defects could be detected with a thermal loading of the sample.

The record of vibration of a truck cabin is given in (c). Electrical casing is small Al part

with rubber coating (d). Bonding quality is tested with artificial defects.

4.3. Laser shearographic system

Modern phase stepping optical systems used for aircraft industry have higher sensi-

bility and signal-noise ratio (SNR) in interferometric methods. Phase stepping optical

configuration (real-time phase, phase circulation and display) enable wrapped phase

mapping of surface deformation. Obtained data serve for signal processing and flaws

detecting. Proper filtering is introduced for better results.

Transferring compact measuring system Q 800 for full field represents contactless

NDT inspection for different materials (composite materials fiber glass reinforced plas-

tics, bonded composite materials). Delaminations, cracks, voids, impact damage, defects