212

5. STRESS ANALYSIS OF AN AUTOCLAVECONSTRUCTION

Upon the request of the company Kolubara Prerada - Vreoci the project of overhaul

and reconstruction of autoclave was realised in cooperation with the Welding Institute,

Beograd.

The autoclave consists of several sub-structures:

-

top spherical lid, connectors for opening the vessel top lid;,

-

top cone shell above the support,

-

middle cone shell and support;

-

bottom cone shell, zone of emptying device, device segments, limiters and draining

boards;

-

spherical bottom lid, connectors, device for opening the bottom vessel lid.

5.1. Problems in the construction of autoclave during the service

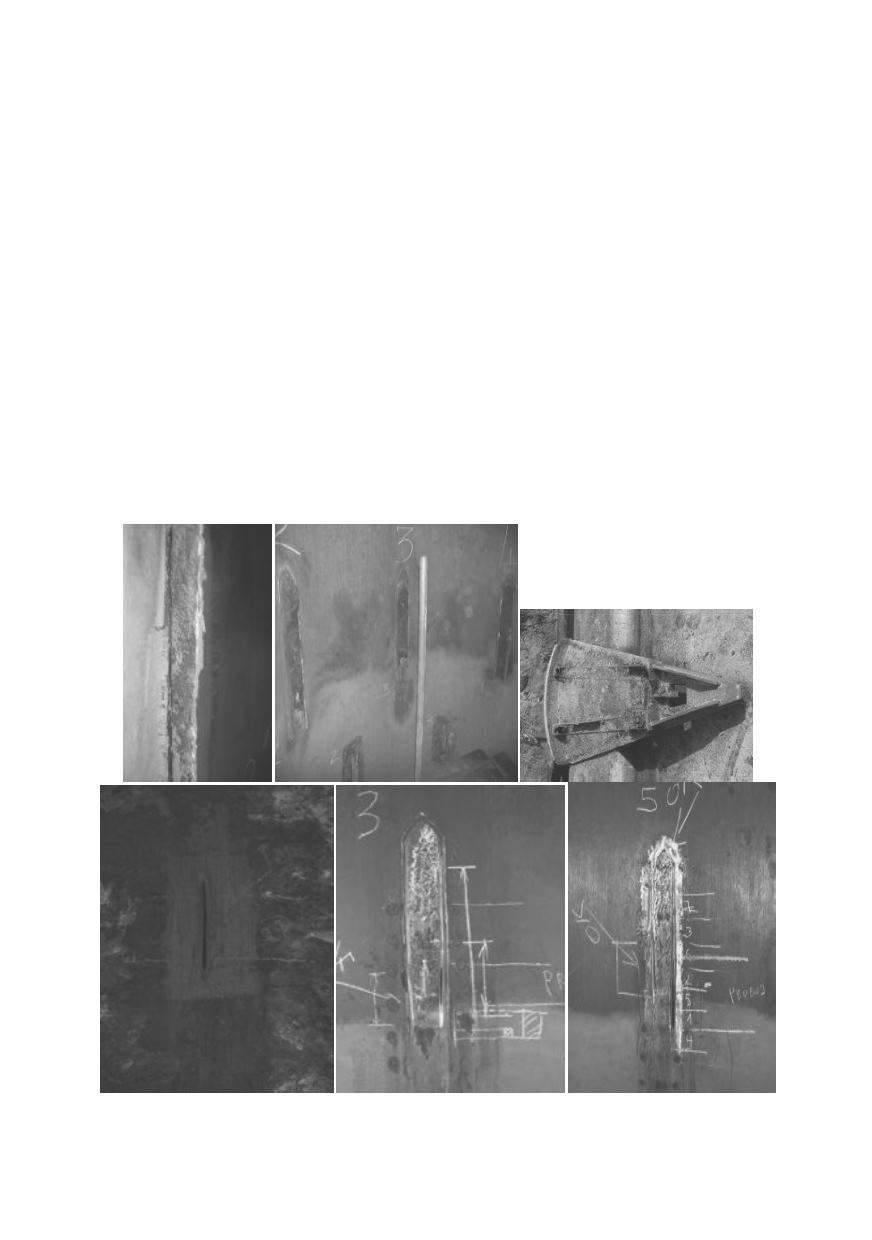

Next problems were established (Fig. 5.1):

the geometry of the segment support allowed to form coal deposits in the support

zone until it is completely blocked;

coal particle movement has caused removal of the basic material in this zone,

cracks occurred due to high stress concentration, and support blockagereduced

shell thickness in the segment support zone, and imperfections in welded joints.

Figure 5.1: Cracks, damages and fracture of autoclave components during the service