233

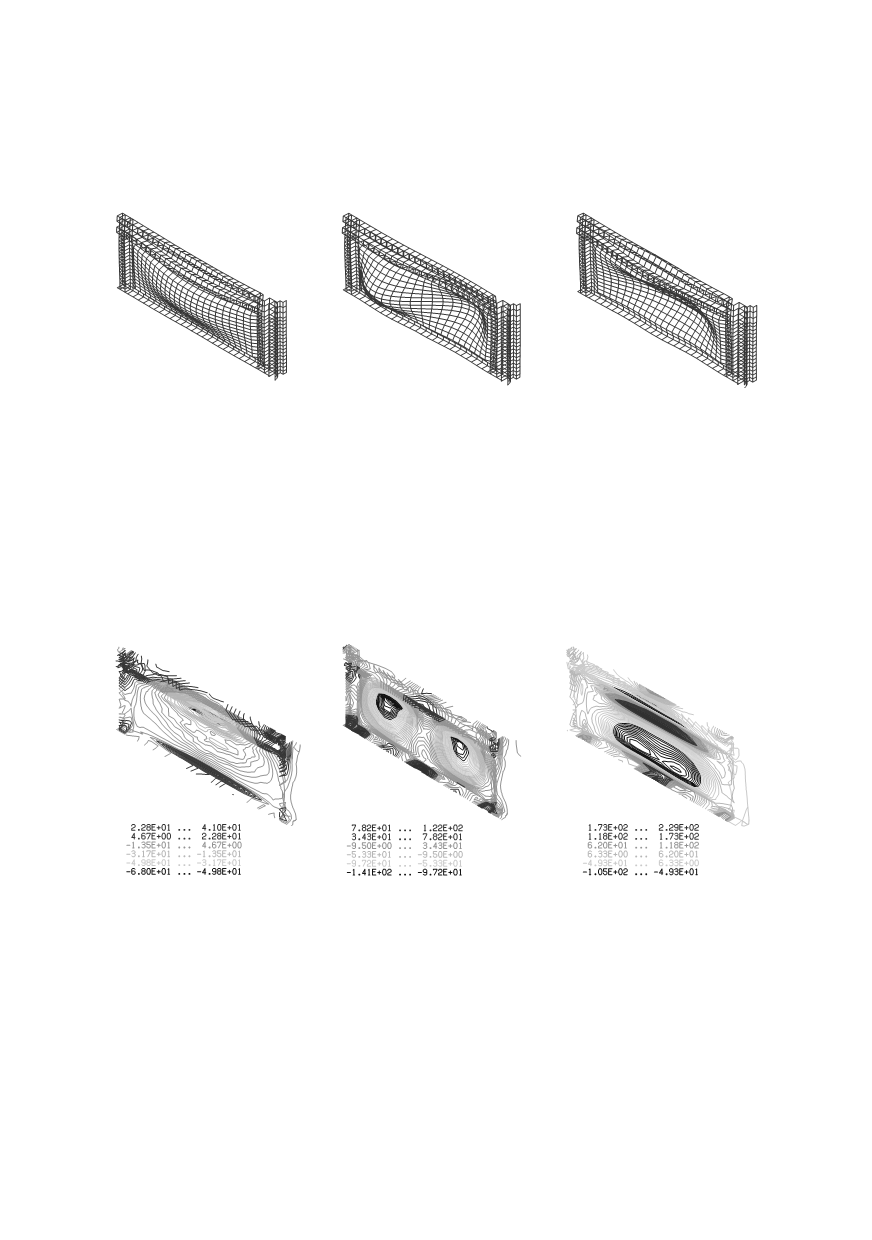

The side walls of a plastic container used for transportation of parcels in aircraft

industry prematurely failed due to excessive deflection (Fig. 5). In order to solve the

problem dynamic behaviour of elements had been analysed on a proper model. The

dimension of side wall were 295 x 142 x 196.5 mm. Performed analysis produced first

three mode shapes (Fig. 5) of the plastic wall supported by hinges along the contour.

Figure 5: The first three mode shapes of the wall side of the container. Obtained frequencies are:

f

o1

= 57.9 Hz,

f

o2

= 97.4 Hz,

f

o3

= 110 Hz

Two types of models were applied in the analysis. First one was initial, unmodified

model, and second one was arbitrary uniformly modified model. It was required that the

changes must be small. Distributions of the increment difference of potential and kinetic

energies assessed by models in initial state and after arbitrary uniform modification of

wall plate are shown in Fig. 6 for the first three mode shapes. This design of the wall

enabled similar dynamic properties as in the thin plate and the introduction of fixed

supports in different locations with the highest growth in kinetic energy enabled

significant improved of dynamic behaviour of modified wall.

Figure 6: Distribution of potential and kinetic energies increments differences (

ΔE

p

-

ΔE

k

), in

initial wall design and after arbitrary uniform modification for the first three mode shapes, kNxcm

The next example of successful mechanical structure reanalysis is the dynamic

behaviour of the intake structure of the piping system in a compressor station (Fig. 7).

Based on energy distribution in structural segments and by modification involved

constraints it was possible to find out that unacceptable dynamic response of pipeline

design is caused by several excitation frequencies closed to the natural frequencies, close

to the resonant regime. Only a small disturbance is sufficient to produce the damage of

steam line structure. The causes of unacceptable behaviour of the steam line in service

were geometry design and applied supporting system. It was not possible to eliminate