198

For this complex inspection following NDT methods had been applied: dimensional

measurement on specified locations andcontrol of diameter and wall thickness at knees,

visual control of steam line and of steam line supports, metallographic analysis applying

the replication of the location of knees, magnetic and ultrasonic testing of welded joints,

hardness measurement of welded joints, and geodetic measurement of steam line in cold

and warm state.

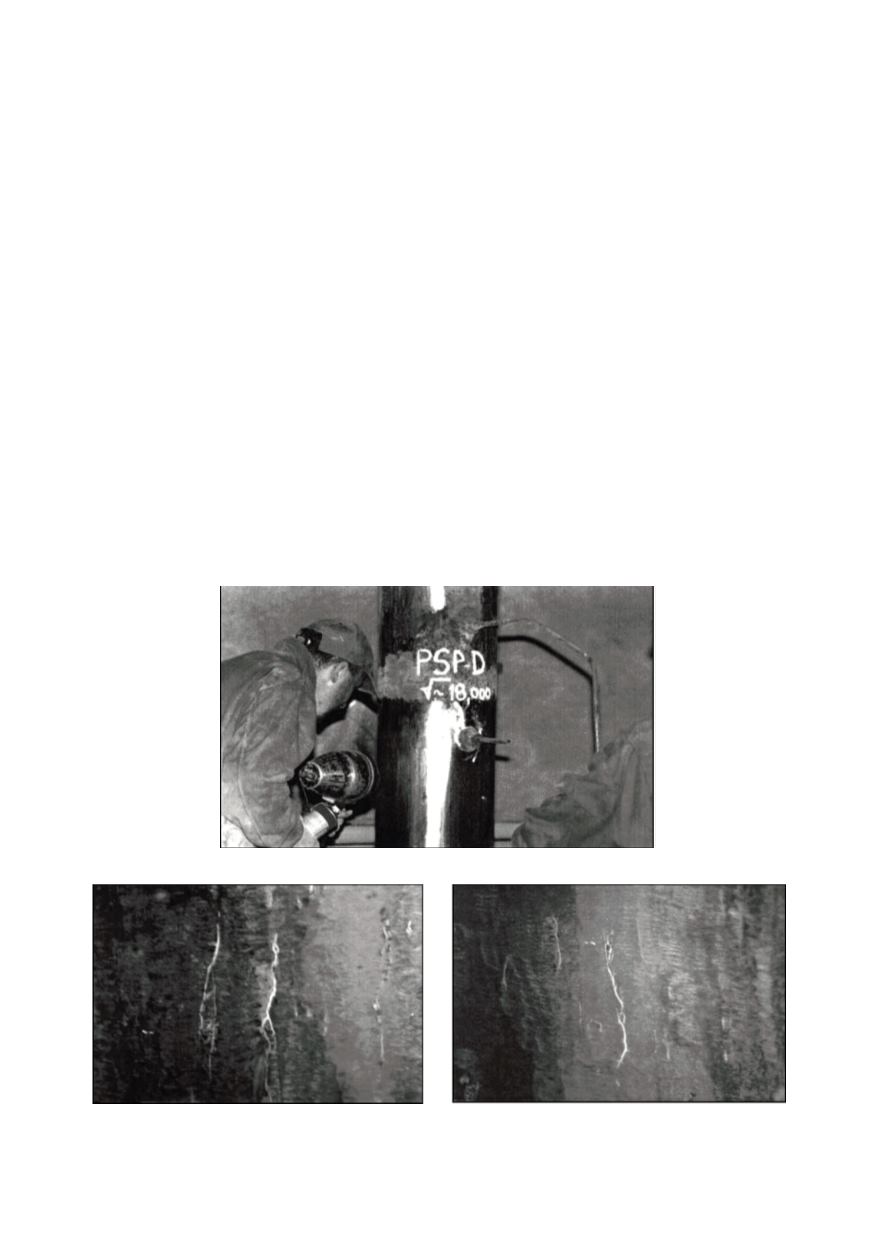

Serious linear indications had been detected on pipes close to welded joints Z1 and

Z9, only by incident, since magnetic particles testing of pipes had not been specified.

The defects on the pipe in the vicinity of Z1 had been grinded out 6 to 7 mm in depth

and repaired by welding. The pipe segment close to welded joint Z9 was cut out in length

of 2200 mm and this segment was replaced by a new one. Chemical composition, che-

cked by stiloscop analysis, was found to be the same for old and new segments.

4.2. Turbineunit 7 in Thermal Power Plant ′′Kakanj′′

Turbine of unit 7 had been inspected in March 2005, during general surveillance of

turbine components according to NDT programme. Outer casings of high and medium

pressureturbines (castings,material ČSN 422744.1)were examined by visual inspection

(Fig. 3), and magnetic particles testing of dividing plane and transition radiuses (Fig. 4).

On the bottom part of high pressure outer casing, cracks, 420 and 30 mm in length,

were detected (Fig. 5). The photograph taken after initial grinding, obtained by magnetic

particles testing, is shown in Fig. 6, and by dye penetrant in Fig. 7. The crack 420 mm

long had been root out after grinding 100 mm in depth of wall 140 mm thick (Fig. 8).

Figure3:Visual inspection of pipes in the vicinity of weldment Z9

Figure 4: The records of magnetic testing indications (Z9)